What is CFS? The secret to optimizing effective LCL shipping in 2025

In the increasingly complex logistics landscape, CFS (Container Freight Station) helps consolidate goods, optimize costs, and shorten delivery time. This article will help you fully understand what CFS is, the services provided at CFS warehouses, and the role of CFS in the supply chain.

1. What is CFS?

CFS (Container Freight Station) is a specialized warehouse area in logistics where LCL (Less-than-Container-Load) shipments—those that are not enough to fill a full container—are consolidated, sorted, and handled. Here, small shipments from multiple shippers are grouped, arranged, and packed together into a larger container for international transportation.

In Vietnam, CFS is simply understood as a receiving and delivery point for LCL cargo, usually located within port areas and under customs supervision. Besides consolidation, CFS warehouses also perform tasks such as packaging, tallying, storage, deconsolidation, or handling transshipment cargo.

Additionally, CFS plays an important role in facilitating LCL import–export activities, helping businesses with small shipments participate in the global logistics chain without having to rent a costly full container.

Read more: Detailed procedure for issuing certificates of origin 2025

2. Main services at CFS warehouses

CFS warehouses provide various services supporting LCL cargo import–export processes, including:

- Receiving, preliminary checking, and storing LCL cargo from multiple shippers.

- Sorting, arranging, and packing or repacking goods according to export requirements.

- Deconsolidation and consolidation services to combine LCL shipments into a shared container.

- Supporting customs procedures and related import–export operations.

- Transporting goods between the CFS warehouse and the port, container stuffing, and delivery to the final recipient.

In addition, some CFS warehouses offer extra services such as transportation, freight forwarding, and advanced warehouse management to optimize logistics operations for businesses.

Read more: The difference between CY and CFS in the transportation industry

3. The role of CFS in the supply chain

So what is the role of CFS in the supply chain? CFS acts as an intermediary hub, consolidating and handling multiple small shipments before packing them into a full container, thereby optimizing costs and reducing the number of transport trips. Thanks to this centralized consolidation process, businesses with LCL shipments can maintain delivery schedules while significantly reducing logistics expenses.

Some key roles of CFS include:

- Transportation optimization: Consolidating many LCL shipments into one container reduces the number of containers needed and cuts transportation costs.

- Improved distribution: Goods are inspected, classified, and repacked (if necessary) to prevent damage and ensure scientific container loading.

- Customs clearance support: Documentation, taxes, and customs checks can be completed at the warehouse, shortening clearance time and reducing errors.

- Risk reduction and increased safety: Goods are stored and monitored in a centralized location, minimizing loss or damage during handling and transport.

- Flexibility: Businesses can adjust transport plans, routes, or delivery methods more easily.

Thanks to these benefits, CFS becomes a key point that keeps the supply chain efficient and stable, especially supporting small businesses accessing international markets more conveniently.

Read more: Shipping to the U.S.: Current situation & process (updated 2025)

4. Understanding CFS fees

In import–export operations, CFS fees are an important cost yet often overlooked when businesses estimate logistics budgets. To manage this cost effectively, understanding the nature and collection process of CFS fees is essential.

4.1. What are CFS fees? Average CFS fee

CFS fees are the costs incurred when goods are consolidated, handled, and prepared for transportation at a CFS warehouse. The average CFS fee typically ranges from 15–18 USD/m³ per container or per shipment, depending on the nature of the goods and the services requested. Common fees include:

- Storage fee: Applied when goods are stored at CFS while waiting for transport.

- Packing fee: For packing, sorting, and preparing goods for container loading; fragile or special-care goods may incur higher charges.

- Handling fee: Includes inspection, sorting, loading, unloading, and packing.

- Customs inspection fee: Charged for document and cargo checks required for customs clearance.

- Transportation fee: Cost of moving goods from CFS to the export port or from the import port to the business’s warehouse.

- Loading/unloading fee: Calculated based on volume or container count during loading or unloading.

Average fees may vary by cargo type, country, port, and additional services. Although CFS fees usually account for a small portion of total logistics cost, they play an important role in ensuring goods are transported safely and on time.

4.2. CFS fee collection process

The CFS fee collection process must ensure transparency so businesses understand logistics costs clearly and avoid unexpected expenses. The process is usually as follows:

Port staff collect fees from the forwarder: When goods enter or leave the CFS warehouse, port staff determine applicable fees (storage, handling, checking, packing…) and collect them directly from the forwarder responsible for the shipment.

Forwarder collects fees from the shipper: After paying the port, the forwarder compiles CFS fees and invoices the shipper. Charges are often based on weight, number of packages, or cargo characteristics. Businesses should choose reputable forwarders to avoid unnecessary extra charges.

Port manages and performs LCL consolidation: Since CFS warehouses are managed by the port, all costs for handling LCL cargo—sorting, consolidation, container packing—are collected here. CFS fees are typically charged at both export and import ends to ensure seamless cargo processing.

Confirmation and completion: After payment, the forwarder or shipper receives receipts or confirmation documents to proceed with customs inspection or container stuffing. This is crucial for smooth logistics and avoiding clearance delays.

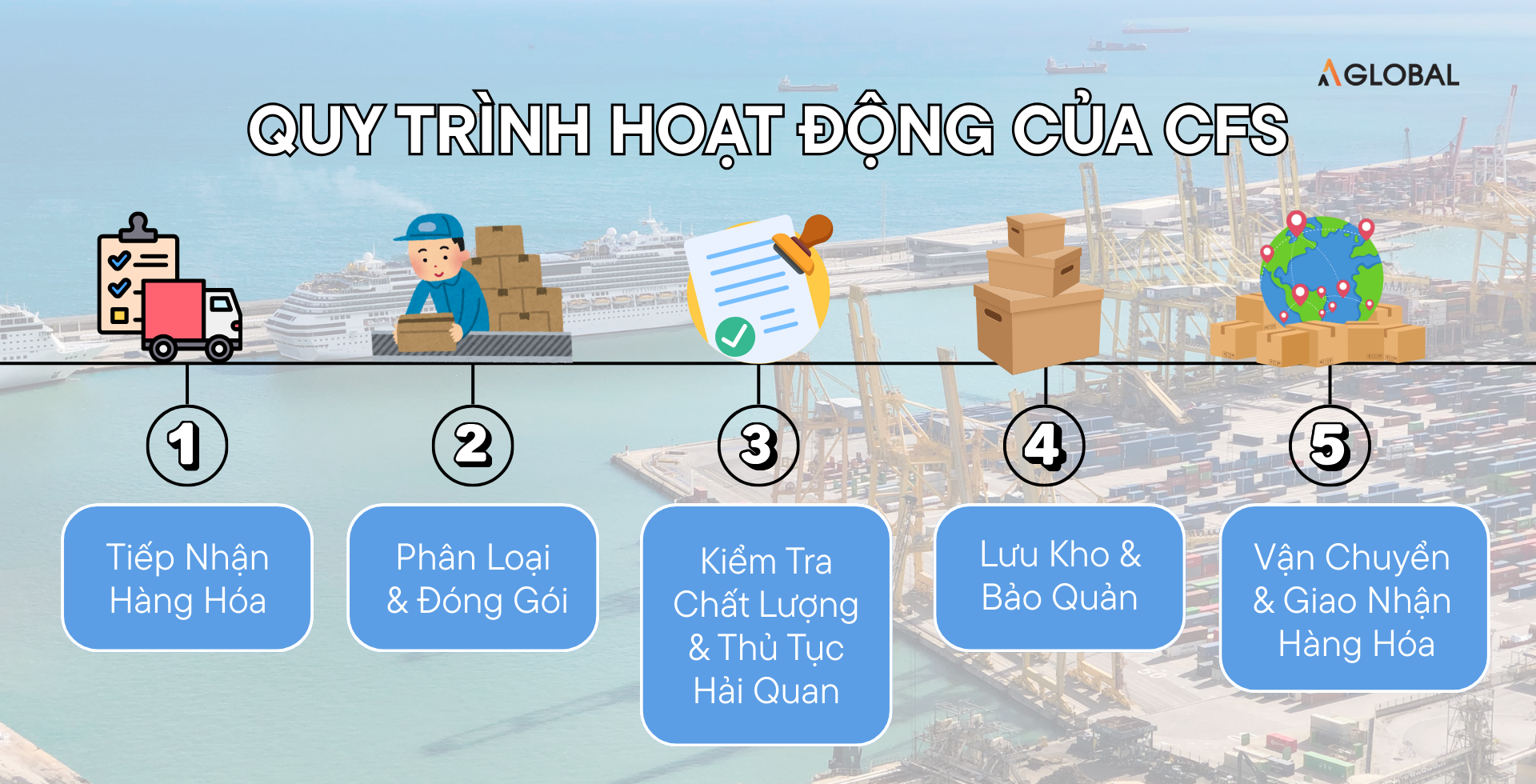

5. CFS operation process

Before exploring the detailed steps, note that every stage of CFS operations—from receiving, sorting, inspecting, storing, to transporting—directly affects product quality, safety, and delivery schedule. Understanding each step ensures the workflow runs smoothly, effectively, and with minimal risks.

Step 1: Receiving goods

The first step at CFS is receiving goods from shippers or agents. CFS staff check the quantity, cargo type, and physical condition of the goods, comparing them with related documents to detect damage or shortages. Information is updated into the management system for accurate tracking.

Step 2: Sorting and packing

After receiving, goods are classified by shipment, destination, cargo type, or transport method to optimize warehouse space and facilitate handling. Some goods may require repacking to protect them during transit or meet international standards. This may include dividing large shipments or adjusting packaging.

Step 3: Quality inspection and customs procedures

CFS conducts quality checks to ensure goods are not damaged and meet import–export standards, especially for sensitive items such as food, pharmaceuticals, chemicals, or fragile goods.

At the same time, customs procedures are completed, including invoice checks, certificates of origin, and related documents to ensure compliance with legal requirements.

Step 4: Storage and preservation

Checked goods are stored in designated areas appropriate to their characteristics (dry goods, perishable goods, dangerous goods…). CFS manages storage conditions and duration to avoid extra costs and ensure goods remain in optimal condition.

Step 5: Transportation and delivery

Finally, goods are moved from CFS to the port or delivered to the next carrier. CFS coordinates with transportation units and customers to ensure smooth delivery and issues necessary documents to finalize the import–export process safely, on time, and cost-effectively.

6. Conclusion

CFS warehouses are an essential link in the global logistics chain, bringing practical value to import–export businesses, especially those dealing with LCL cargo. Understanding what CFS is and maintaining transparent fee management helps businesses plan better and enhance competitiveness in international trade.

AGlobal – the best cross-border e-commerce solution for businesses.

Register for a free 1-on-1 consultation tailored to your industry Here!